Today, as the home appliance industry accelerates towards quality and intelligence, the processing accuracy and stability of glass components have become core competitiveness. The requirements for cutting edges, strength, and appearance consistency are constantly increasing for gas stove panels, oven door glass, microwave oven windows, water heater display glass, and various home appliance touch glass panels. The new generation of glass laser cutting machine independently developed by Chuangkeda is becoming a new standard for home appliance glass processing with high precision, stability, and wide adaptability, fully meeting the cutting needs of multiple categories of home appliance glass.

01 High precision cutting, comprehensively improving glass quality

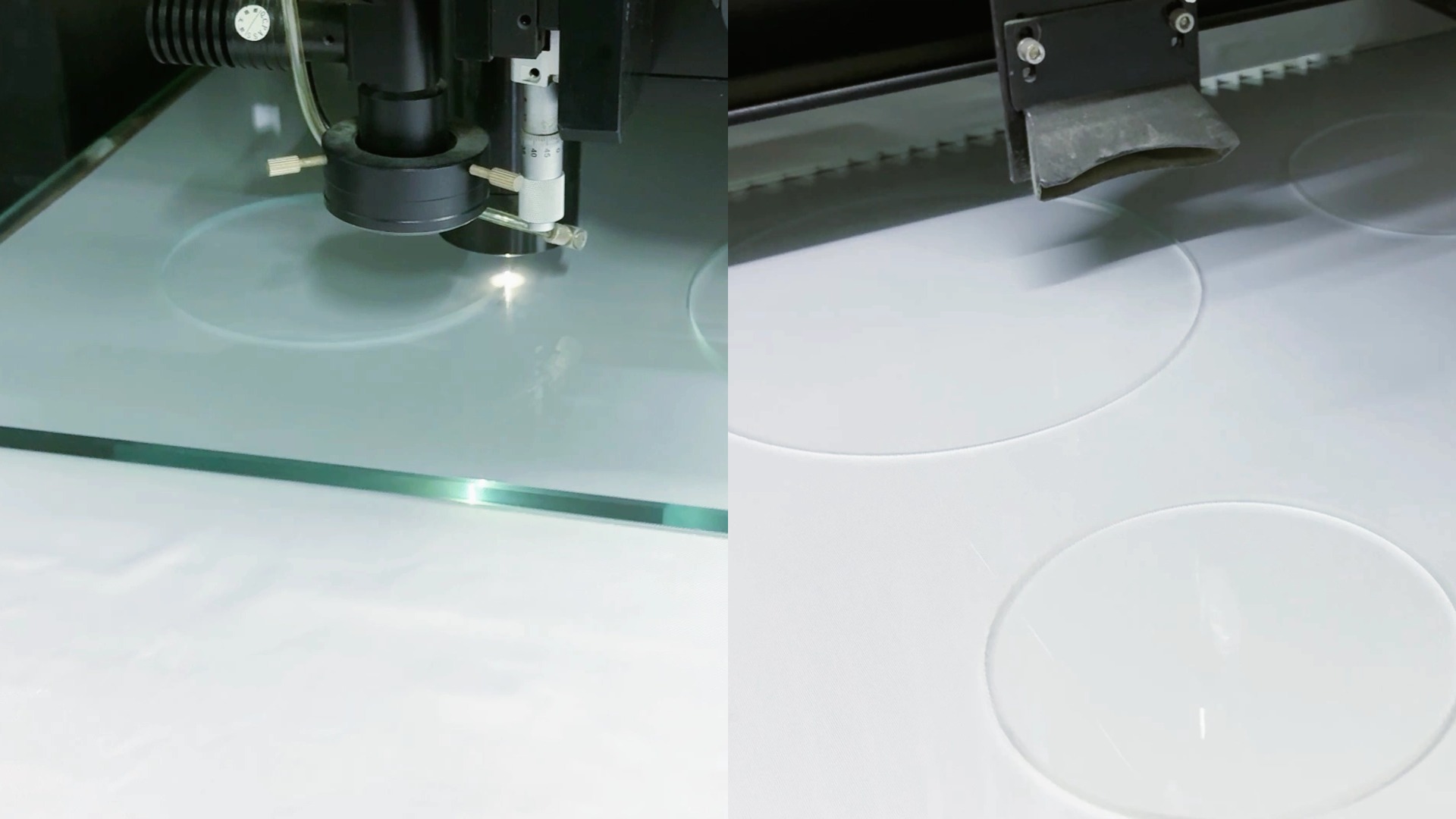

Traditional mechanical cutting is prone to problems such as large edge breakage, multiple microcracks, and unstable size, and requires a large amount of edge grinding and polishing, resulting in high cost and low efficiency. The Chuangkeda glass laser cutting machine adopts infrared picosecond laser, carbon dioxide fragmentation and cold processing technology to directly cut in a non-contact manner, achieving a precision of ± 0.01mm and a broken edge ≤ 5 μ m. The incision is smooth and undamaged, without the need for secondary grinding or polishing, improving the overall strength and aesthetics of home appliance glass.

At the same time, Chuangkeda's "Glass Laser Cutting Machine" is suitable for cutting gas stove glass panels, oven door glass, microwave window, water heater display glass, and touch glass panels. It can efficiently complete difficult processing such as irregular structures, micro hole positions, chamfers, narrow borders, etc., providing more freedom for product appearance upgrades and structural innovation.

02 Stable and efficient, helping to speed up the production line

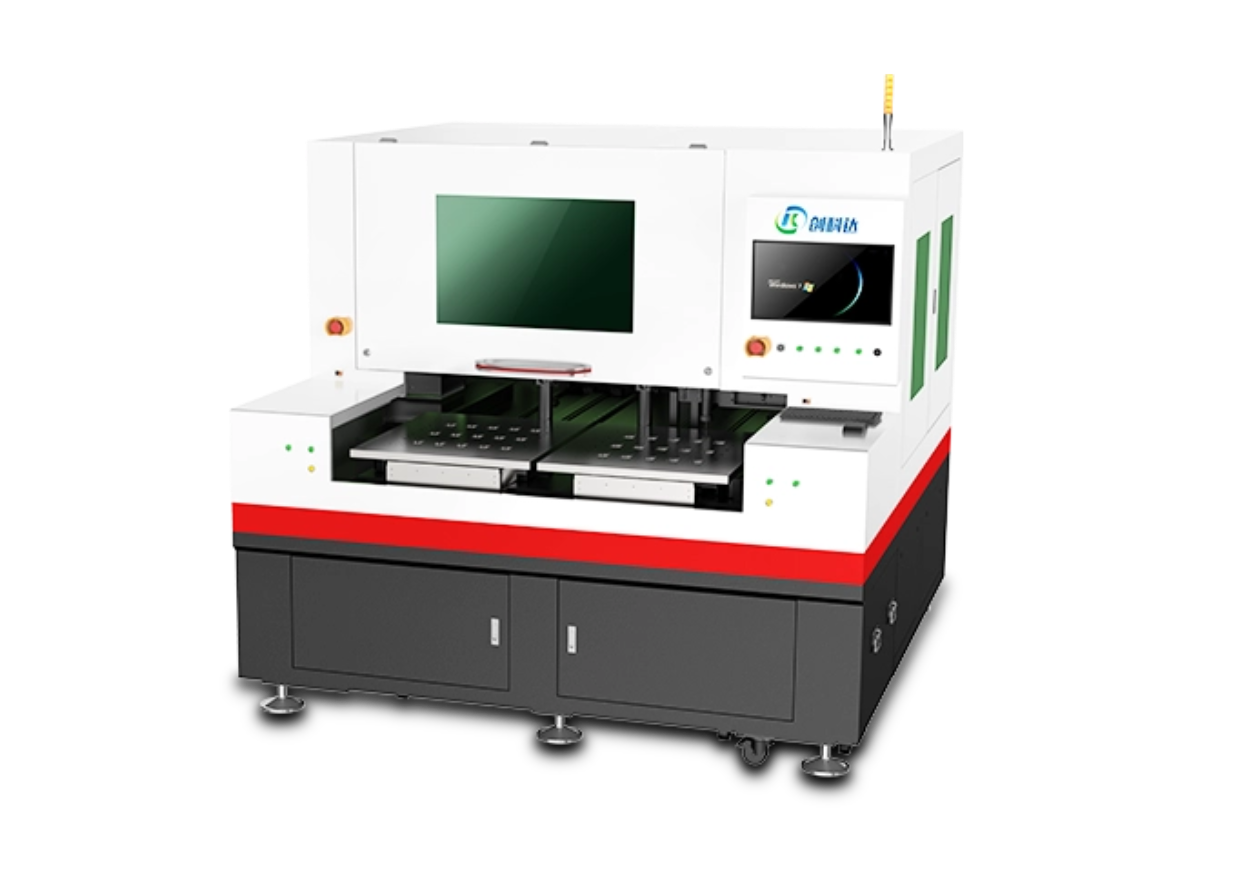

The device supports continuous operation for 7 × 24 hours and can be equipped with functions such as automatic loading and unloading, intelligent typesetting, and dynamic focusing. It can seamlessly integrate into home appliance glass production lines, significantly improving daily production capacity.

The CCD visual positioning system ensures stable and consistent trajectories, and modular design makes maintenance easier, helping factories reduce labor and operating costs.

03 Multi scenario adaptation, covering all categories of home appliance glass

The Chuangkeda laser cutting solution is widely used in:

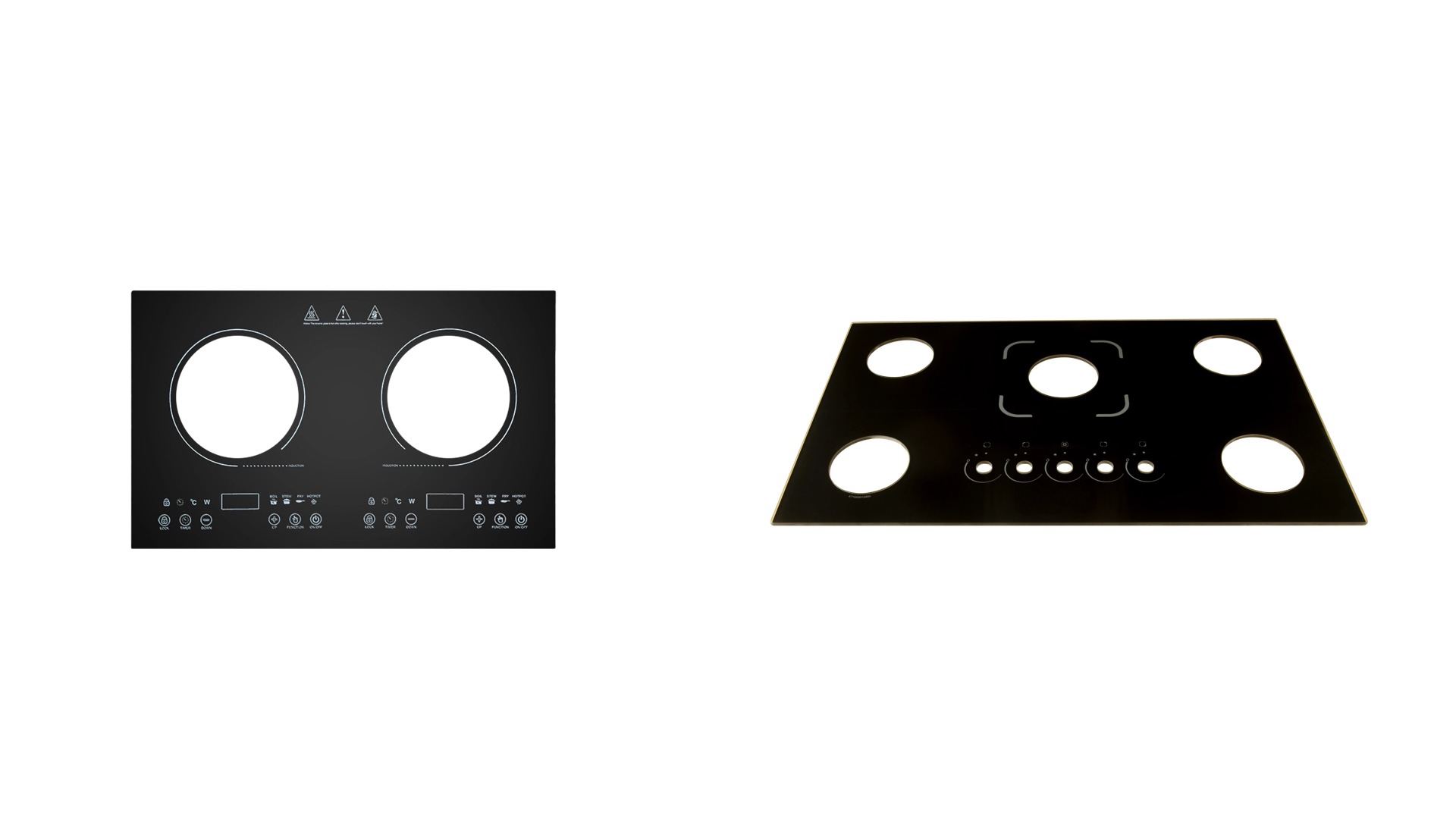

Gas stove glass: high strength, no micro cracks

Oven door glass: shaped and chamfered in one go

Microwave oven window: neat edges, precise positioning

Water heater display glass: narrow edge hole position

• Touch panel: suitable for coating, screen printing, ultra-thin glass

From kitchen appliances to intelligent displays, Chuangkeda provides customers with high standard and high stability laser cutting solutions, helping the industry upgrade its quality.