In today's increasingly competitive home appliance manufacturing industry, from the panels of gas stoves and trays of microwave ovens to the shelves of refrigerators and observation windows of ovens, glass components not only serve functional purposes but also represent crucial elements of product aesthetics and quality. Traditional glass cutting methods, plagued by efficiency bottlenecks, high loss rates, and inconsistent edge quality, are hindering enterprises' rapid response capabilities and cost control.

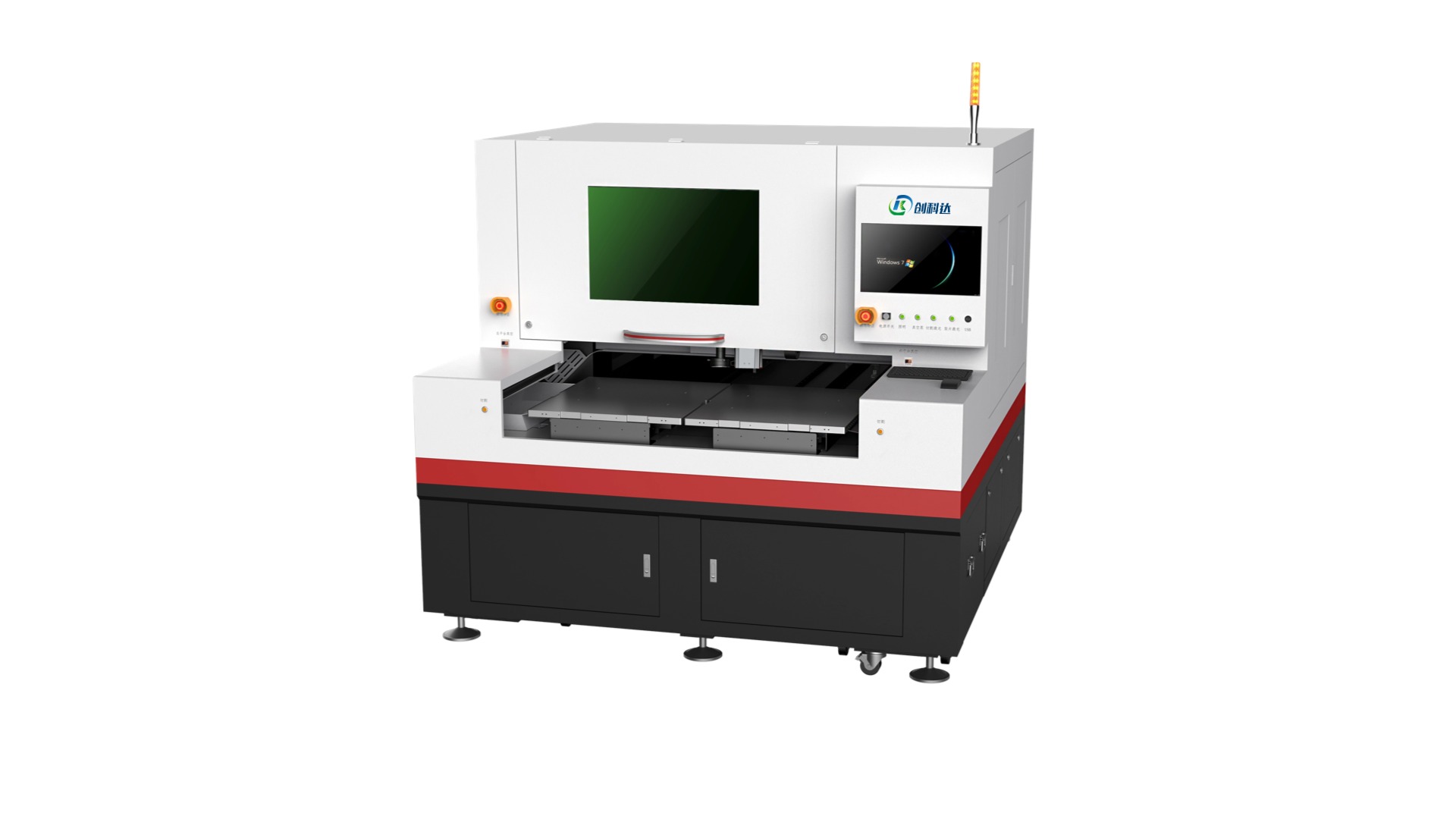

To address this, Chuangkeda's professional glass laser cutting solutions, with their innovative technology, are becoming the optimal choice for processing home appliance glass components, empowering enterprises to achieve comprehensive competitiveness enhancement.

I. Ultimate Efficiency, Accelerating Time-to-Market

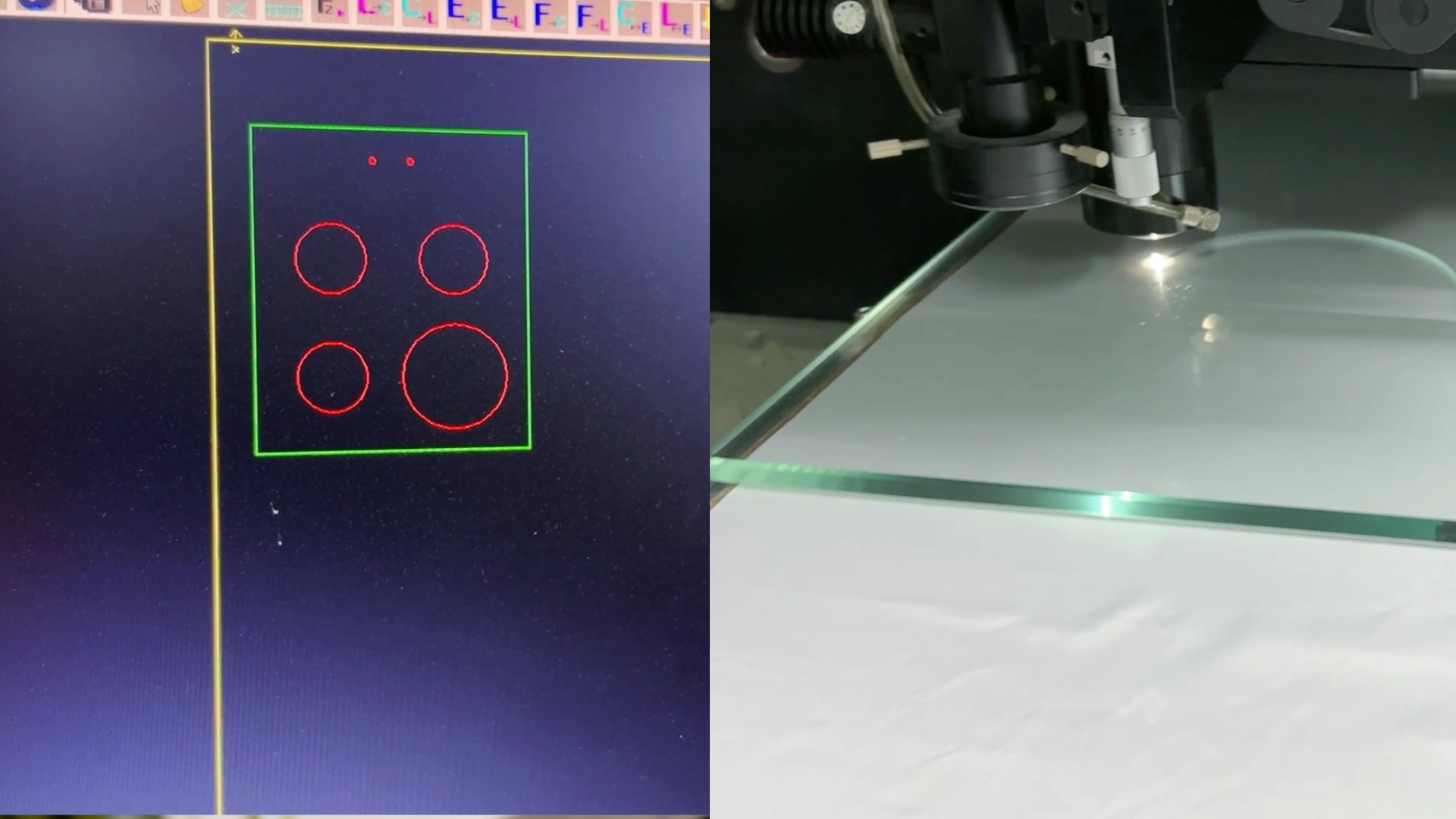

Chuangkeda laser cutting equipment employs non-contact processing, eliminating the need for molds. Instantaneous, high-precision cutting of any shape is achievable directly from digital drawings. Whether it's complex openings (burner holes, control holes) on gas stove panels or standard rectangular refrigerator shelves, processing can be completed within seconds. This completely eliminates the time required for mold preparation and line changeover adjustments in traditional methods. Production batch switching is flexible and smooth, making it particularly suitable for customized and high-end home appliance production with small batches and multiple varieties, enabling your products to seize market opportunities faster.

II. Exceptional Quality, Bestowing Products with Superior Detail

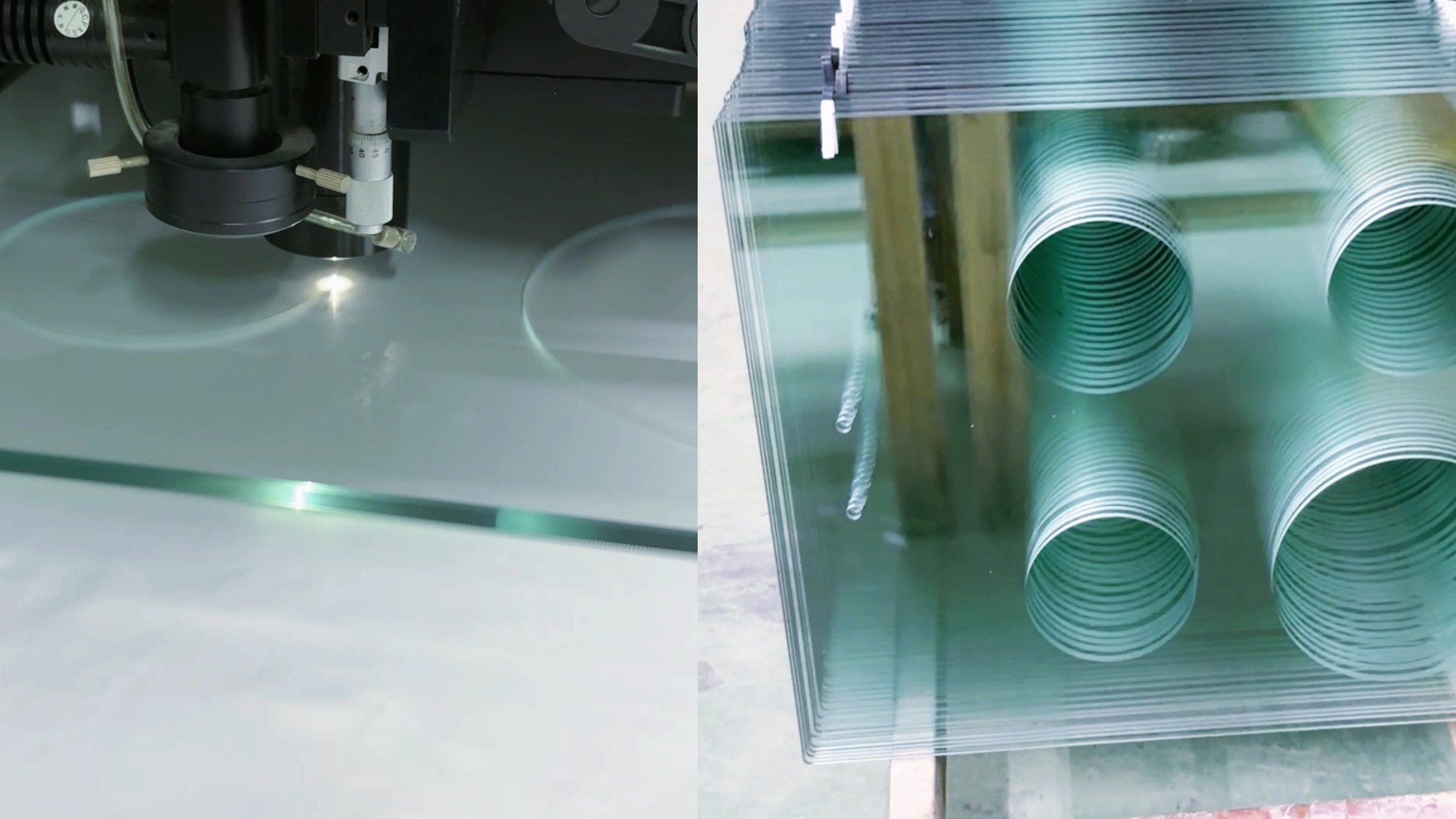

Laser cutting has an extremely small heat-affected zone, producing smooth, flat cutting edges free of micro-cracks. This translates to:

Higher Strength: Significantly improved edge impact resistance, reducing hidden damage during subsequent transportation and assembly.

Enhanced Aesthetics: Edges are clear and transparent, requiring no secondary polishing, achieving an "optical-grade" effect directly, and elevating the overall texture of the appliance.

Guaranteed Consistency: Fully digital control ensures identical cutting quality for every piece of glass and every batch, eliminating the dimensional and edge variations common in traditional cutting.

III. Significant Cost Reduction, Optimizing Overall Production Costs

The direct results of high efficiency and superior quality are substantial reductions in overall costs:

Material Costs: Maximizes glass utilization through intelligent nesting software, reducing waste.

Tooling Costs: Eliminates expensive diamond cutting tools or molds; no consumable wear.

Downstream Process Costs: Excellent edge quality eliminates complex post-processing steps like grinding, cleaning, or stress relief.

Management Costs: Digital production significantly increases yield rates, reducing the difficulty of quality control and material management.

IV. Broad Applicability, Comprehensively Covering Home Appliance Glass Applications

Our equipment technology is mature and capable of stably processing various types of glass materials used in the home appliance field, including but not limited to:

Tempered Glass: Used for gas stove cooktops, oven door panels.

Heat-Resistant Glass: Used for microwave oven trays, oven observation windows.

Ordinary Flat Glass: Used for refrigerator shelves, decorative panels.

Enameled Glass: Used for colored panels on high-end cooktops and refrigerator doors.

Choosing Chuangkeda glass laser cutting equipment is not just selecting a machine; it is adopting a comprehensive solution that propels home appliance glass manufacturing towards an efficient, precise, and flexible future. Chuangkeda is committed to helping enterprises rapidly transform innovative designs into high-quality products while maintaining firm cost control, securing initiative in the fierce market competition.