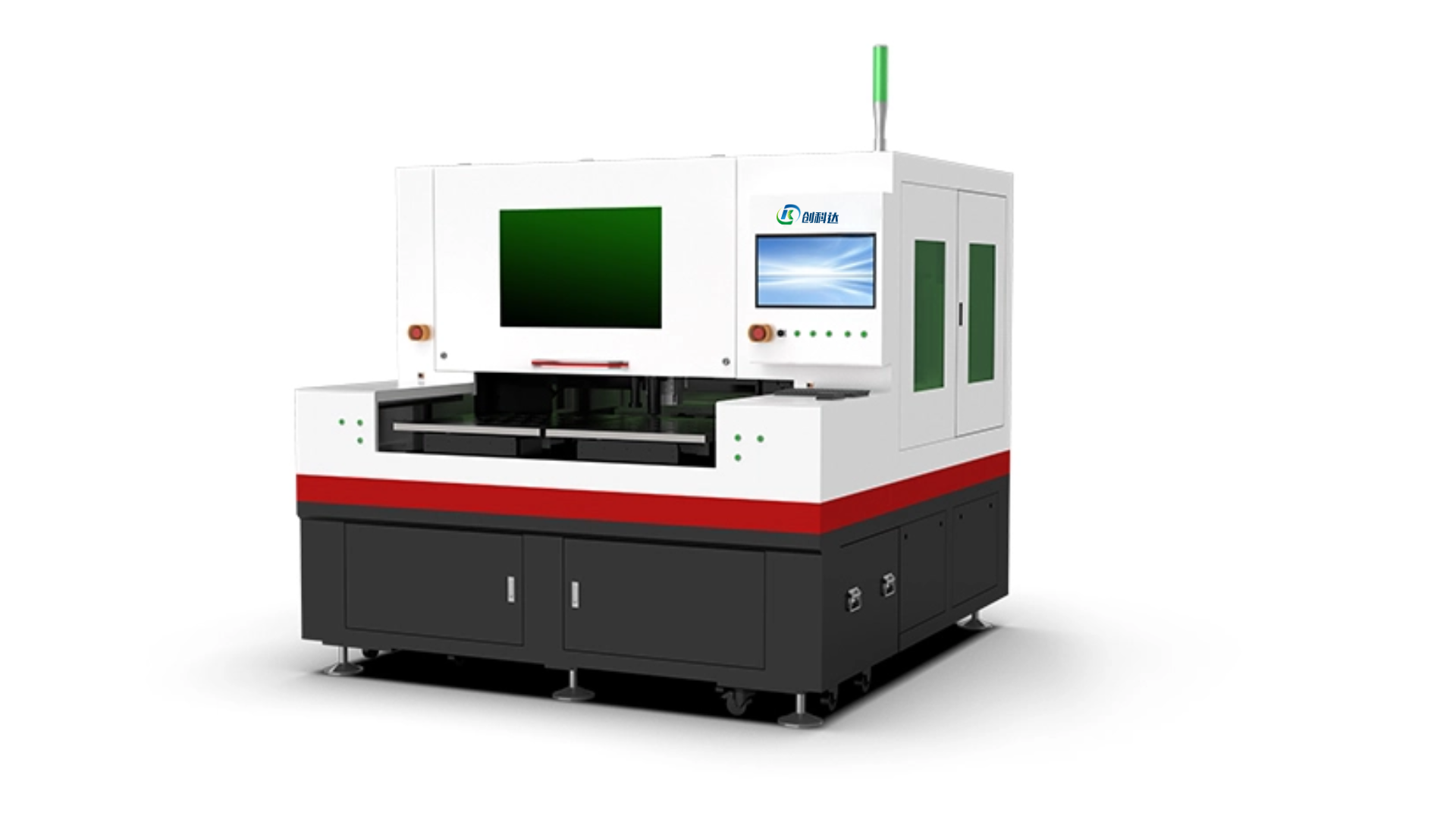

In the pursuit of ultimate precision in modern manufacturing, glass cutting technology is facing unprecedented challenges and opportunities.Traditional mechanical cutting methods are gradually showing limitations in the processing of high-end materials such as optical glass and special glass - microcracks are difficult to avoid, edge roughness restricts accuracy, and complex shapes are difficult to achieve. We are well versed in this field and, with years of accumulated laser technology, have launched a new generation of intelligent glass laser cutting systems, redefining the standards of precision cutting.

1、 Breakthrough in core technology to achieve perfect cutting

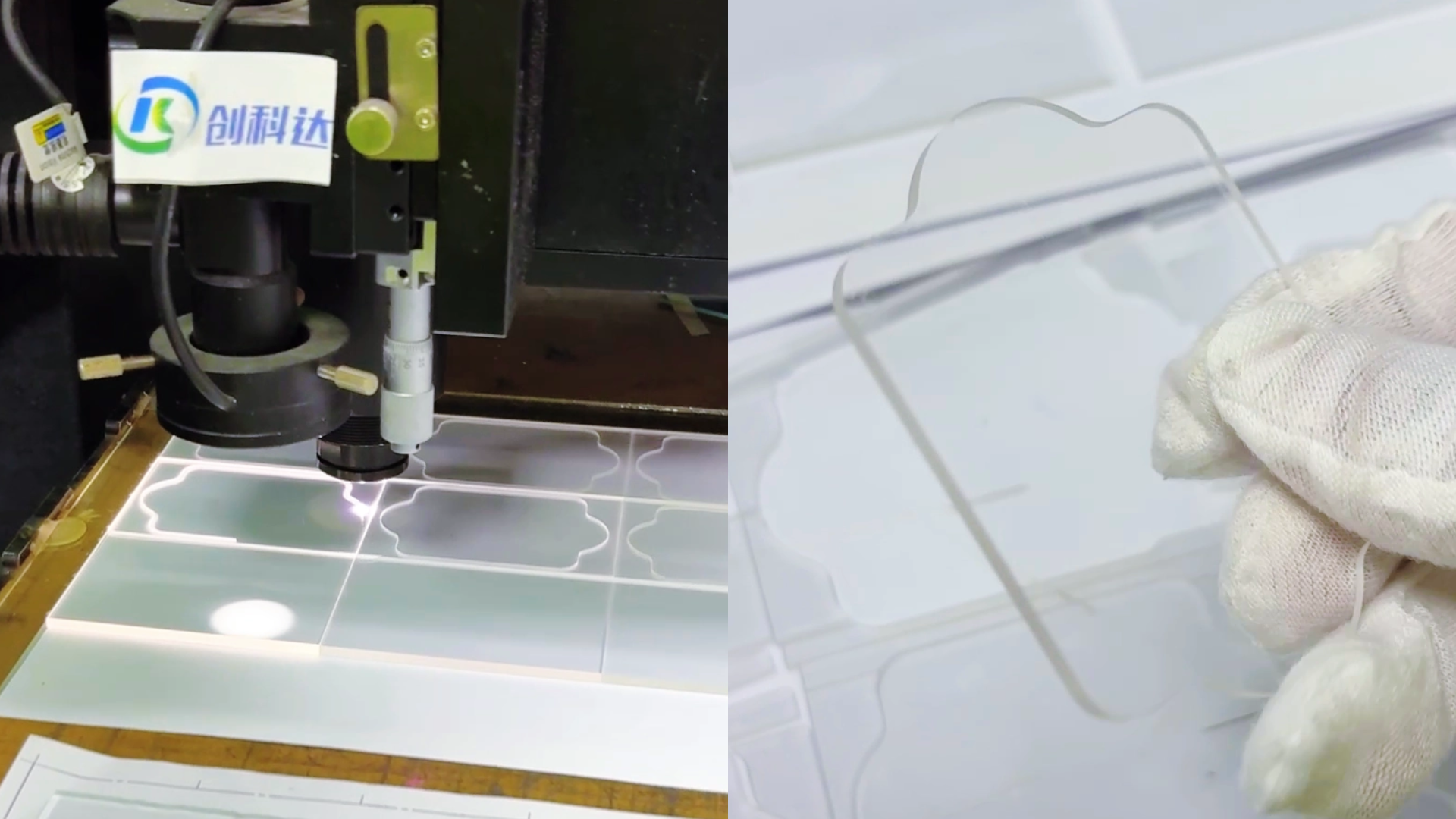

The Chuangkeda laser cutting system adopts a unique non-contact processing technology, which fundamentally avoids the micro cracks and edge collapse phenomena caused by traditional mechanical cutting through the controllable laser thermal stress induced separation principle.

▶ Excellent compatibility performance:

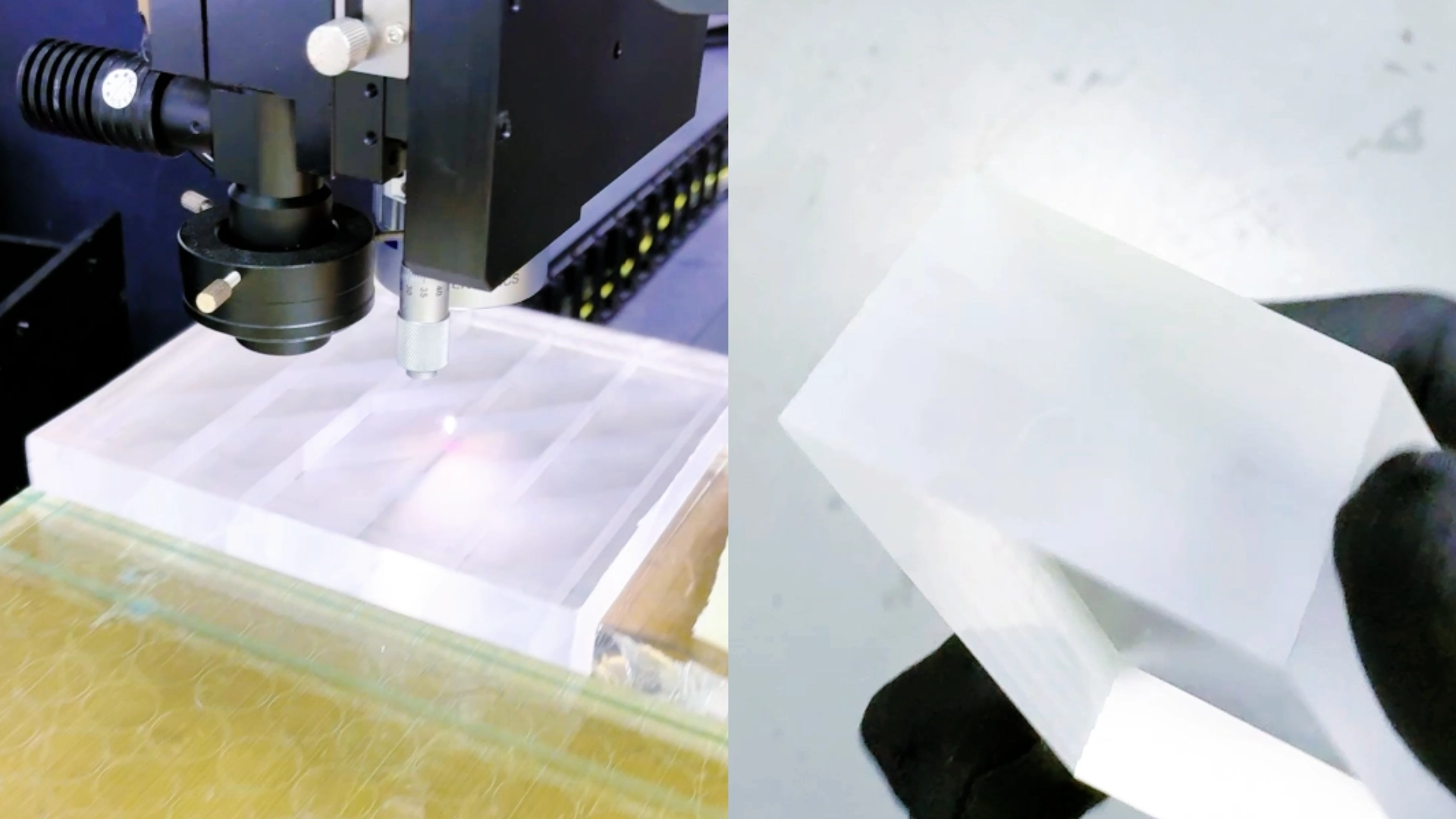

(1) Easily handle various optical and specialty materials such as K9, quartz glass, high borosilicate glass, sapphire glass, etc.

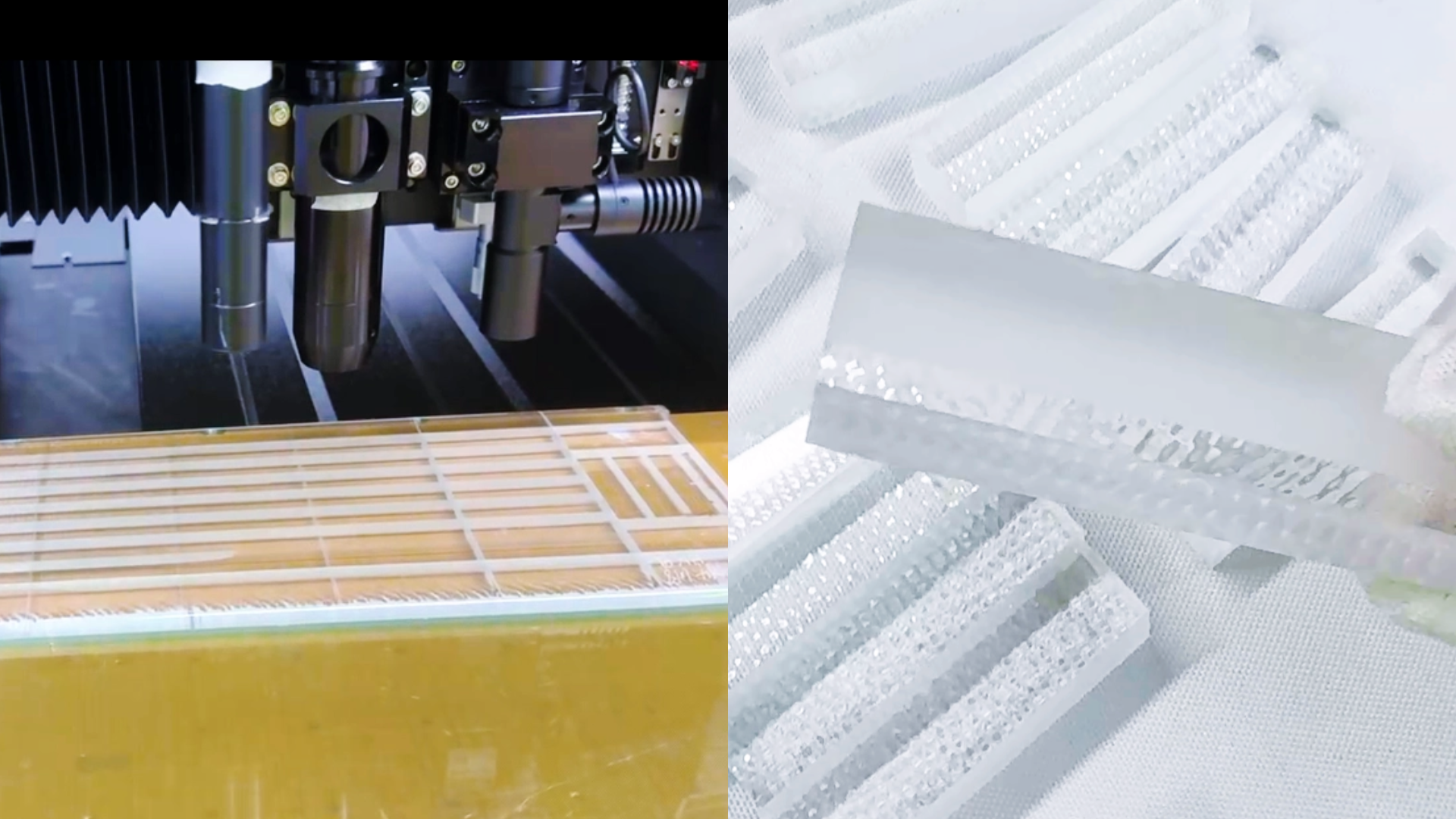

(2) The cutting thickness range is wide, from 0.01mm ultra-thin glass to 25mm thick glass, which can be perfectly processed.

(3) Adaptive parameter adjustment system, intelligently matching the physical properties of different materials.

▶ Unparalleled cutting quality:

Cutting accuracy ± 0.01mm, edge breakage ≤ 0.5 μ m, smooth and even cutting surface, no need for secondary polishing or grinding treatment.

2、 Empowering intelligent systems to enhance comprehensive benefits

Chuangkeda Equipment not only focuses on cutting quality, but also strives to comprehensively improve customers' production efficiency and economic benefits.

▶ Intelligent operation platform:

(1) Equipped with a self-developed visual positioning system, it automatically identifies material edges and defects.

(2) Supports one click import of multiple file formats such as DXF, DWG, AI, etc.

(3) Intelligent typesetting algorithm maximizes material utilization and reduces losses by up to 15%.

▶ Efficient production performance:

(1) The cutting speed is increased by 3-5 times compared to traditional methods, significantly shortening the delivery cycle.

(2) 24-hour continuous and stable operation, with a comprehensive utilization rate of up to 95% for the equipment.

(3) Remote monitoring and diagnostic system to achieve preventive maintenance and reduce unexpected downtime.

3、 Widely applied in the industry, creating diverse value

The Chuangkeda laser cutting system has proven its outstanding value in multiple high-end manufacturing fields.

▶ Optoelectronic industry: precision optical components, filters, display glass cutting.

▶ Semiconductor field: wafer carrier board, sensor protection cover plate processing.

▶ Automotive manufacturing: Glass molding for in car displays and head up displays (HUDs).

▶ Medical equipment: precision processing of microscope slides and observation windows for medical instruments.

▶ Research field: customized experimental equipment, production of special shaped optical components.

Chuangkeda firmly believes that technological innovation is the fundamental driving force for enterprise development.