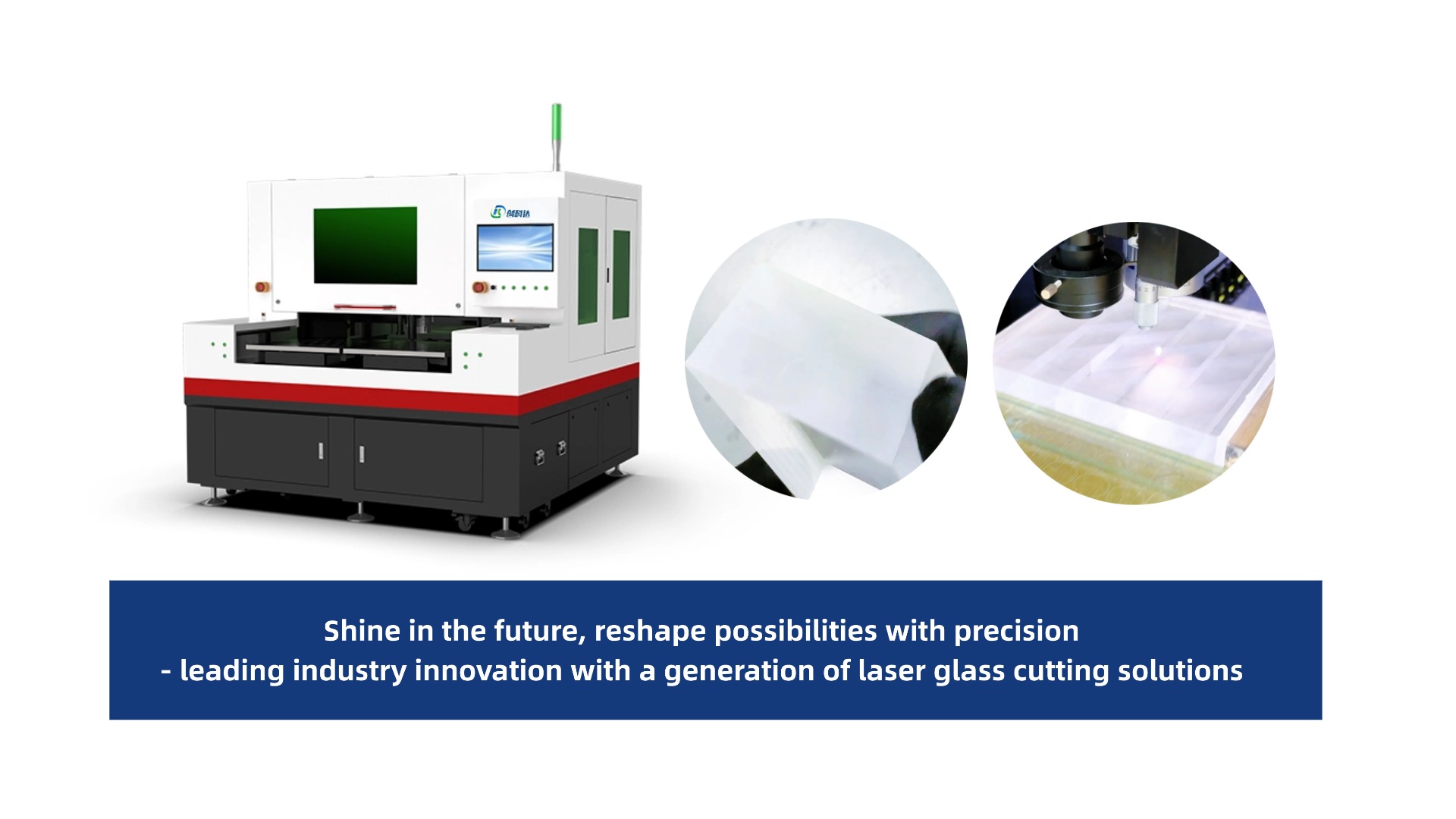

With the continuous advancement of industries such as smartphones, automotive displays, wearable devices, and optical components toward higher performance and precision, traditional glass processing techniques are increasingly struggling to meet the demands for precision, yield, efficiency, and environmental sustainability. Achieving finer cuts, cleaner edges, lower material loss, and higher efficiency has become a core focus for glass deep-processing enterprises. In response to this trend, Chuangkeda has independently developed the "Infrared Picosecond Laser Glass Cutting and Breaking Integrated Machine," offering a cutting-edge solution with leading optical technology and high-end equipment capabilities.

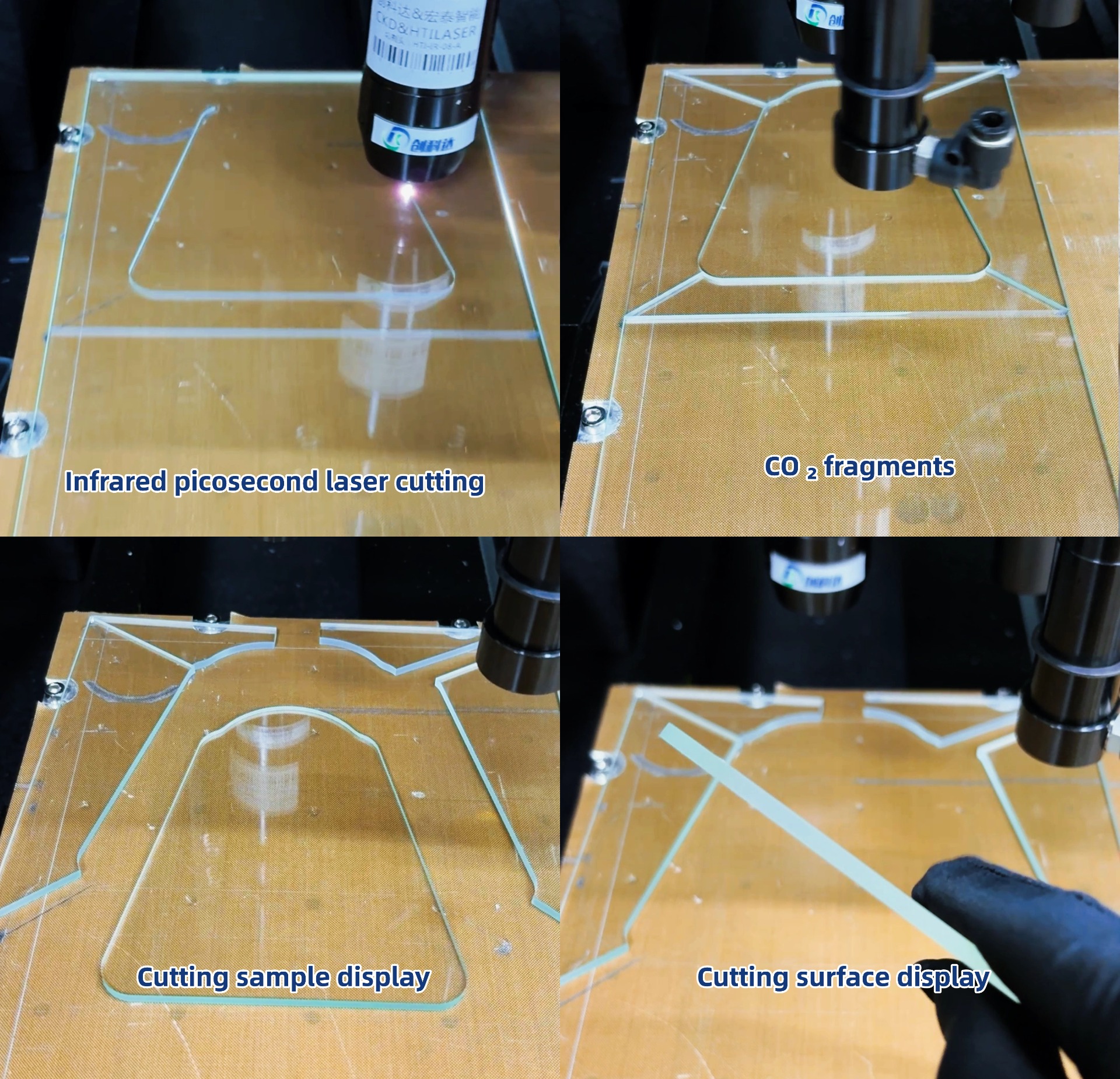

1. High-Power Picosecond Laser + CO₂-Assisted Breaking for More Efficient Integrated Processing

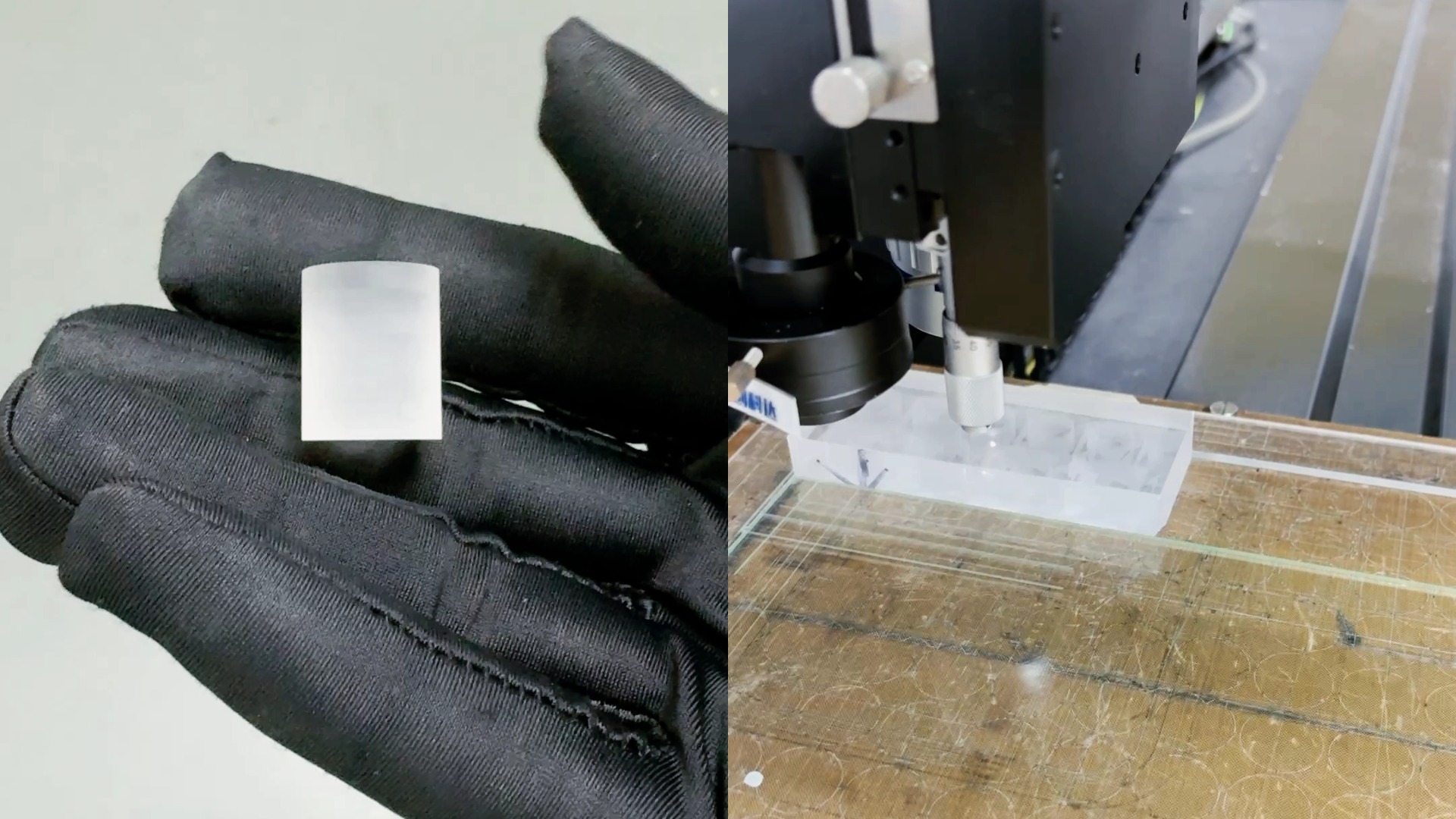

The machine employs a high-power infrared picosecond pulsed laser with a pulse width of <10ps, delivering high peak power and minimal thermal impact. This enables precise micro-explosion effects within the glass, achieving internal separation and high-quality cutting paths.

Paired with CO₂-assisted breaking technology, the system integrates cutting and breaking into a single process, ensuring stable, controllable cutting lines while enhancing edge smoothness and flatness.

To accommodate diverse processing requirements, Chuangkeda offers two modes: pre-cut pre-break and pre-cut post-break, allowing users to flexibly choose based on glass type, thickness, and product structure, significantly improving process adaptability.

2. Precision Mechanical Structure: Micron-Level Positioning for Long-Term Stability

High-end processing equipment requires a stable mechanical platform. The machine features:

· X/Y linear motor drive system

· German 0.1 μm digital grating ruler (positioning accuracy ≤±2 μm, repeatability ≤±1.5 μm)

· Maximum linear speed of 1000 mm/s

Combining high-speed motion with high-precision feedback ensures consistency and repeatability in cutting irregular, curved, or micro-structured glass. The machine and optical platform are built on a natural marble base, providing structural stability and resistance to deformation, effectively countering long-term vibration effects and maintaining exceptional processing accuracy over years of use.

3. Outstanding Cutting Performance: Faster, More Precise, and More Stable

Extensive real-world testing has demonstrated the machine’s superior capabilities:

· Wide cutting thickness range: 0.03–25mm

· Adjustable cutting speed: 0–500mm/s

· Minimal chipping: ≤5μm

· High cutting precision: ±0.01mm

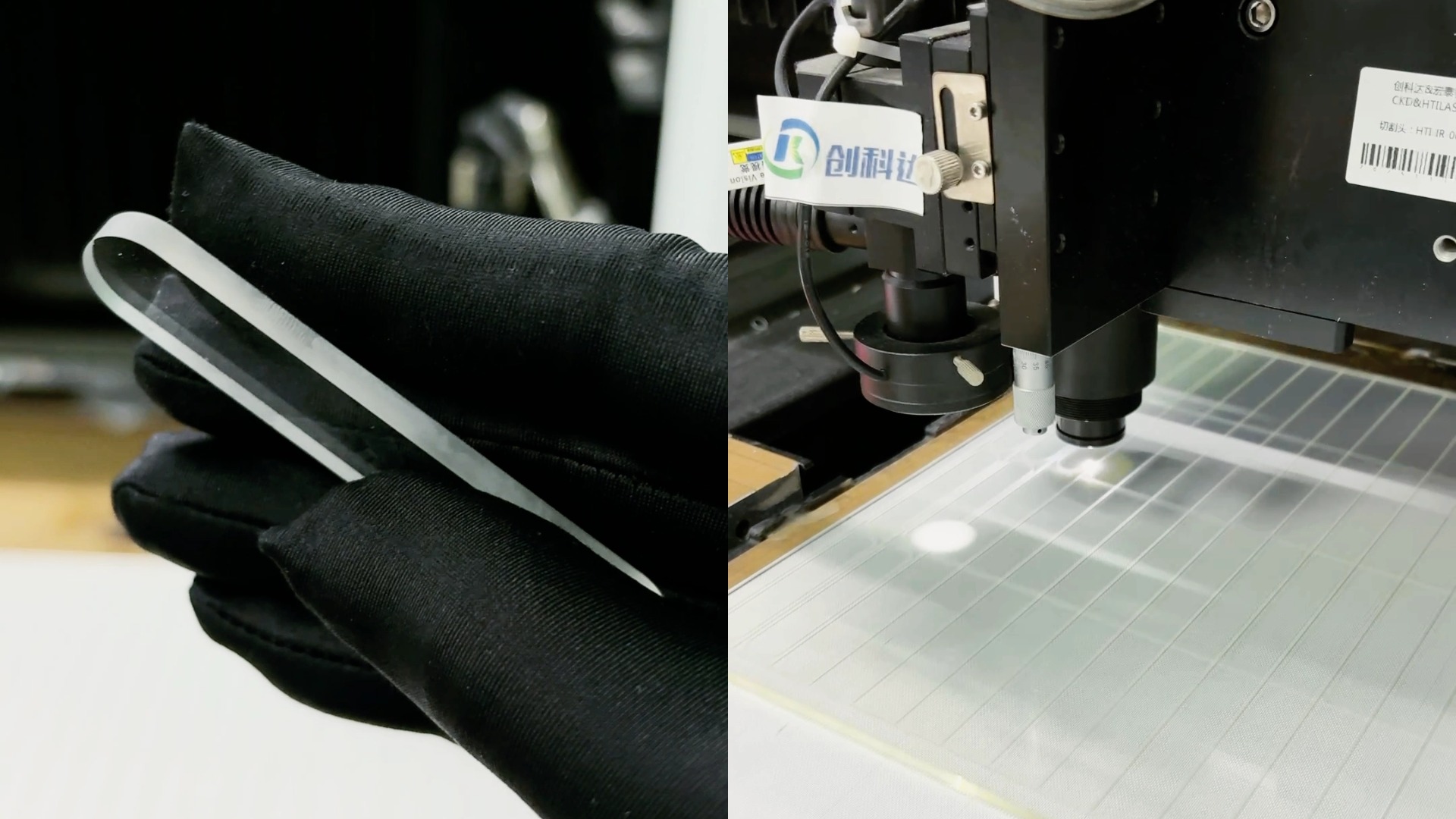

· Excellent edge quality: No taper, burrs, or need for secondary processing

Thanks to picosecond laser cold processing, the glass exhibits no heat-affected zones or crack propagation, with edges stronger than those produced by traditional cutting methods.

4. Broad Applications: Consumer Electronics and High-End Optical Manufacturing

The machine is compatible with various materials, including:

· Ultra-clear glass, standard clear glass, high borosilicate glass

· Quartz glass, K9 optical glass, sapphire glass

Applications include:

· Smartphone cover glass, automotive display glass

· Camera lens protection glass, sapphire lenses, sapphire light strips

· Optical filters, mirrors, and other high-end optical components

· Precision irregular glass parts, small-sized glass structures

Whether for high-transparency optical glass or scratch-resistant sapphire covers, the machine delivers stable, high-quality results across diverse scenarios.

5. Eco-Friendly, Cost-Effective, and High-Yield

Compared to traditional mechanical or thermal cutting, picosecond laser processing is a true cold-working method:

· No dust, wastewater, or chemical pollution

· Minimal consumables, easy maintenance

· Cut edges are ready for subsequent processes without polishing

· Exceptionally high yield reduces material waste

For companies pursuing green manufacturing and cost optimization, these advantages are significant.

6. Smart Operation: Easy to Learn and Use

The machine features an intuitive interface and intelligent control algorithms, enabling quick mastery. With auto-focus, auto-compensation, and other smart functions, even operators with limited experience can achieve high-quality processing effortlessly.

The Chuangkeda Infrared Picosecond Laser Glass Cutting and Breaking Integrated Machine is more than just equipment—it represents a next-generation solution for glass processing. It empowers manufacturers to achieve high precision and quality while balancing efficiency, stability, and environmental sustainability.