phone:联系人:

13714630748(白先生)

18124150753(王先生)

屏幕修复专线:13145848466(潘生)

fax:0755-85279156

mailbox:ckdseiki@126.com

address:Meicheng Industrial Park, Langjing Road, Dalang Street, Longhua District, Shenzhen

How to troubleshoot abnormal situations such as missing holes, missing tracks, and wavy lines during laser cutting?

2023-05-29

Laser cutting trajectory information collection refers to the acquisition and analysis of the position, velocity, acceleration and other parameters of the laser head in the process to obtain the information of the cutting trajectory. This information can be used to optimize cutting parameters and improve cutting quality and efficiency.

In the process of cutting, how to troubleshoot the abnormal situations such as missing hole, missing track, wavy cut, and dislocation of cutting track

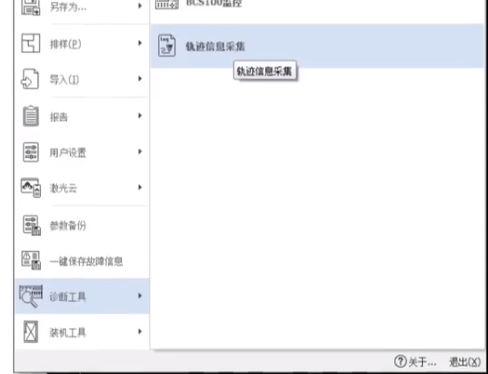

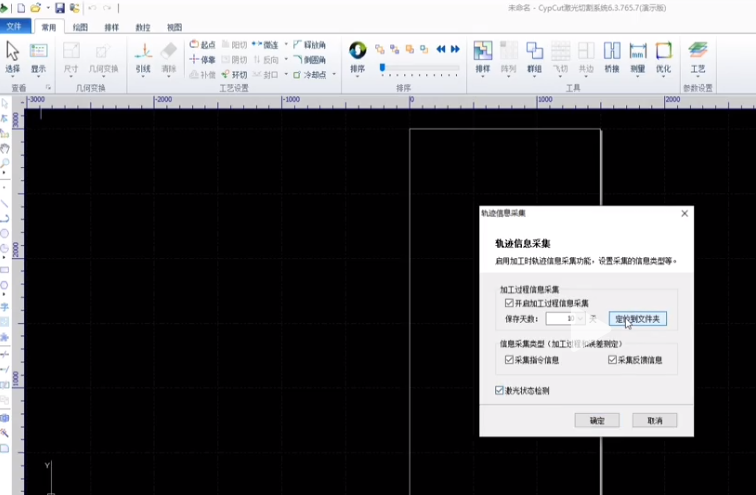

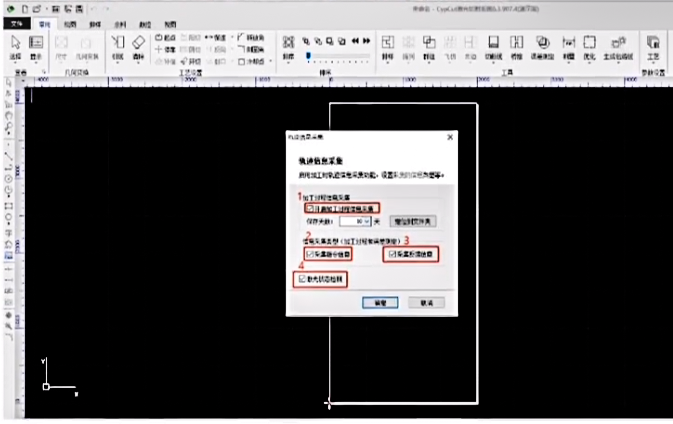

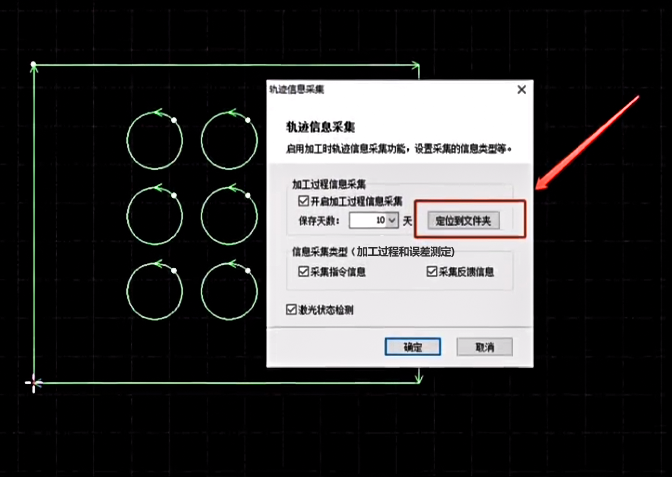

1. Open the File menu - Diagnostic Tools - Track Information Collection Function - Select Collect All Information - OK

2. Check "Enable Information Collection during Processing" [Collection instruction information] [Collection feedback information] [Laser state detection] in turn.

-

1. How to troubleshoot hole leakage and track leakage during processing?

1. How to troubleshoot hole leakage and track leakage during processing?

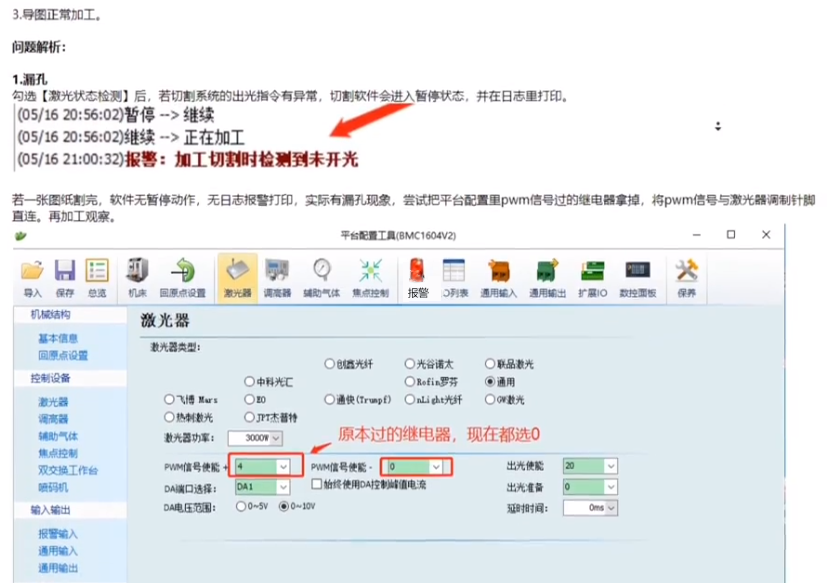

After "Laser state detection" is checked, if the light output instruction of the cutting system is abnormal, the cutting software will enter the suspension state and print in the log.

(05/1620:56:02) Pause --> Continue

(05/1620:56:02) Continue --> In process

(05/1621:00:32) Alarm: unlit is detected during machining and cutting

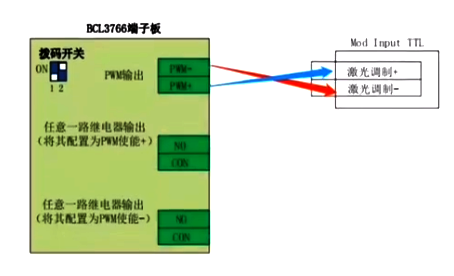

If a drawing is cut, the software does not suspend action, and no log alarm is printed, and there is actually leakage phenomenon, try to remove the relay with pwm signal in the platform configuration, and connect the pwm signal with the laser modulation pin

Direct connection. Reprocessing observation.

When the pwm signal of the board is directly connected to the modulation pin of the laser, if leakage still occurs, check whether the laser is properly grounded and whether the laser itself is abnormal.

-

2. How to schedule production for offset position?

-

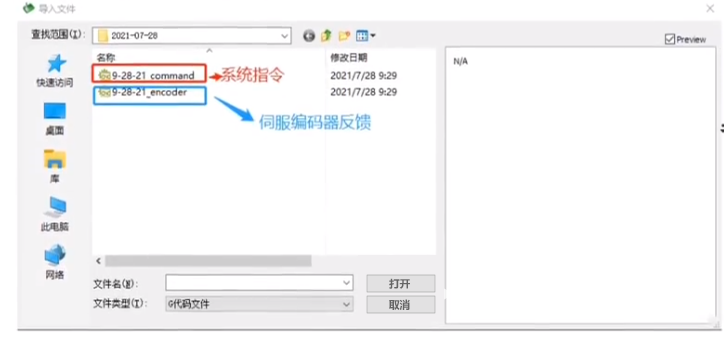

After the problem of cutting deviation occurs, record the time in the lower right corner of the current computer and find the NC file corresponding to the time.

2. How to schedule production for offset position?

After the problem of cutting deviation occurs, record the time in the lower right corner of the current computer and find the NC file corresponding to the time.

Click Navigate to Folder

如果图纸、系统采集信息、伺服编码器反馈三者一致,那么我们就需要排查机械原因了,例如:电机、减速机。