phone:联系人:

13714630748(白先生)

18124150753(王先生)

屏幕修复专线:13145848466(潘生)

fax:0755-85279156

mailbox:ckdseiki@126.com

address:Meicheng Industrial Park, Langjing Road, Dalang Street, Longhua District, Shenzhen

The power is close to the ceiling, and what way can be used to improve the processing efficiency of laser equipment?

2023-07-07

Generally, we want to improve the processing efficiency of the most direct way to improve the laser power, but after the release of 60,000-watt laser cutting machine, it has fully replaced the ability of plasma and flame cutting, and the effect of high power on cutting efficiency and cutting accuracy is no longer so obvious, but it increases the cost and energy consumption of users. But the pursuit of efficiency in the industrial field is endless, if the power has touched the ceiling, what can be done to improve the processing efficiency?

For material properties

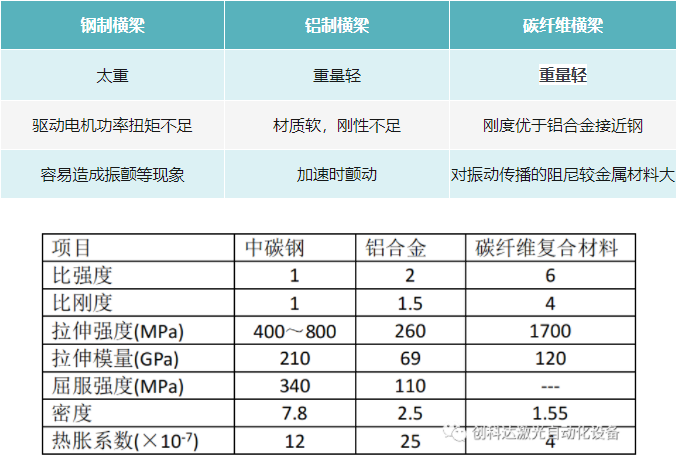

At present, the beam of the machine tool is made of metal, mainly steel and aluminum alloy casting.

The steel cast beam has the advantages of good stability and high precision, but because of its high weight, it is usually used in machine tools with low speed requirements. To achieve high speed and high acceleration, the motor needs to match a large amount of power and torque. When the dynamic matching exceeds the limit, it cannot be further improved. In order to reduce the weight of the beam, people began to use aluminum alloy beam, but the weight of the aluminum beam is still too large, the speed and acceleration is limited, and the aluminum alloy material has low modulus, soft, easy deformation, large thermal expansion coefficient, and the accuracy is susceptible to temperature changes. Therefore, aluminum alloy beams often need to be re-calibrated in 3-6 months.

Carbon fiber beams have the characteristics of light weight, high strength, good corrosion resistance, high durability and design freedom, and are suitable for structural support and load-bearing components requiring light weight, high strength and durability.

The weight of the carbon fiber beam is 1/4 to 1/5 of the steel and 1/2 to 1/3 of the aluminum alloy, which makes it possible to further improve the speed and acceleration of the machine tool. According to Mr. Liu, after the introduction of carbon fiber beams, the flying laser research and development team, after a lot of efforts, has raised the acceleration of the past precision cutting machine generally 0.8g-1g to 2g, and the accuracy has also been increased from the past silk level to μ level while the acceleration has doubled.

For cost

For the user, the carbon fiber beam is also when the acceleration of the machine tool is increased from 1g to 2g, which means that the user only needs to spend a little more money than in the past to buy a piece of equipment, which can achieve the effect of buying 2 pieces of equipment in the past, greatly improving the value of the whole machine, and can also play a very obvious cost reduction effect.

Thermal processing resulting in a large number of machining will form residual stress in the metal, with the passage of time, the residual stress is gradually released, will cause bending deformation of the beam, affecting the accuracy of the equipment. Even if repeated heat treatment, still can not be eliminated. The aluminum alloy beam is precisely soft and easy to deform, which will bring huge after-sales costs to the enterprise, and will also cause users to stop production and wait for maintenance.

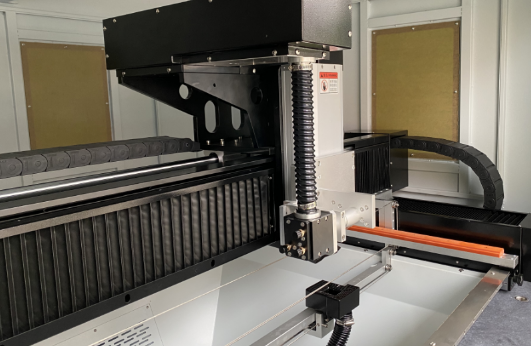

High power laser cutting machine

The carbon fiber does not have plastic deformation, so after the material withstands a lot of external force and has a large deformation, as long as it does not cause internal damage to the material, after the external force is lifted, the carbon fiber composite material can bounce back to the original state without permanent deformation. This property is far superior to metal materials, so carbon fiber composite materials are also applied to elastic components (such as shaker spring plates), whose elasticity is durable and stable without attenuation. When used in high-speed machine tools, even if there are serious accidents such as crashes and unbalanced jams on both sides of the drive, the beam is deformed, and after the accident is lifted, it can be returned to the original state and the accuracy can be maintained.